Products Products

About Raw yarn, staple fiber, and nonwoven fabric

The company added a variety of functionalities and sensitivities to the raw yarn of ECOPET® by changing fiber shapes and thicknesses or by processing.

The advancement of fiber technology enabled ECOPET® to deliver new value, such as recycling, environmental friendliness and to continue evolving as a material that makes people’s daily lives better.

Functionalities added by fiber shapes

SHAPE

case01

- Outline

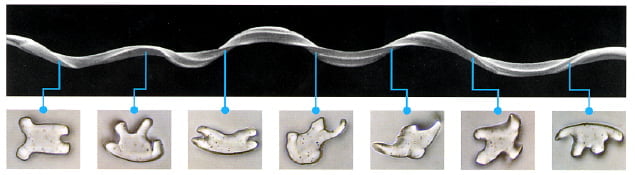

- This new functional polyester has a unique cross-sectional shape comprised of four flat mountains.

- Functions

- Features multi-functionality, including softness and draping, sweat absorption, quick-dry, anti see-through and windbreak functions.

- Grooves created on the fiber surface by four mountains → Sweat-absorption and quick-dry functions achieved by capillary action

- Irregularities created on the fiber surface by four mountains → anti see-through function achieved by the scattering of passing light

- Low bending rigidity due to the flat cross-sectional shape → Soft and draping function

case02

- Outline

- Polyester fiber with a new feel, featuring high sweat absorption, quick-dry, dry-touch, and lightweight functions

- Functions

-

- Water absorption and drying characteristics: Twice as high as those of conventional products, making it a non-sticky, dry-touch material

- Wash durability in terms of sweat absorption: More than twice that of conventional products

- Lightweight

case03

- Outline

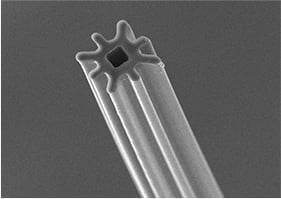

-

- By leveraging our unique technology to create yarn with odd cross-sectional shapes, we arranged eight protruding objects radially on a hollow fiber to let the gaps between fibers created by the eight protruding objects provide different functions.

- Potential for broader use that can be achieved by combining it with other materials via false twisting, combination of different filaments, or twisted yarn spinning

- Functions

- Sweat absorption, quick dry, lightweight, heat shield, heat insulation and dry touch

case04

- Outline

- Light, warm, thermal polyester fiber that contains ‘dead’ air due to its hollow structure

- Functions

-

- Rate of hollowness: 35% to 40%

- So light it floats on water

- High elasticity and firmness

Functionality and sensitivity achieved

by the thinness of the fibers

THINNESS

case01

- Outline

-

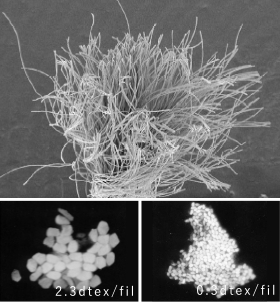

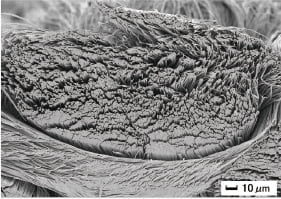

- Special polymer and microfiber of 0.3dpf created via ultrafine fiber yarn-making technology

- Directly spun yarn that is different from split fibers or super thin yarn of the Kaito type

- Tender feel achieved by ultrafine fibers

case02

- Outline

-

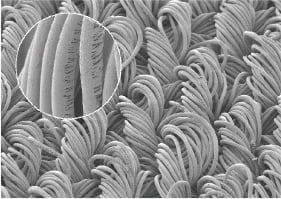

- The surface area of textiles made from nanofibers is dozens of times larger than that of conventional fibers.

- Compared to conventional fibers, it has higher water absorption and adsorption performance and a higher anti see-through property.

- The texture of the textile is soft, causing little skin irritation.

- It has a wide range of uses, such as functional sportswear, innerwear, skin-care products, antibacterial filters and precision polishing cloths.

Characteristics obtained by conjugating fibers together

CONJUGATE

case01

- Outline

- Highly crimped fiber, natural appearance, stretch textile, low luster hybrid worsted-type material

- Characteristics

-

- Features a wool-like fluffy feel, spun-touch, resilience, elasticity, and firmness.

- Wool-like natural appearance with low luster and vivid colors

- Products that have stretch and anti-wrinkle properties, that can be tailored and are easy-care

Functionalities achieved by processing

PROCESS

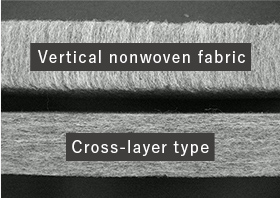

case01

- Outline

- Vertical nonwoven fabrics that have fibers lined up vertically can become a high-quality fiber cushioning material featuring high resilience foam, bulkiness, lightweight and high breathability by combining them with high-performance raw staple fiber. Moreover, they are easy to bend and mold. Sound absorption can be controlled by combining with a surface material or via pressing.