HISTORY History of ECOPET®

1995

ECOPET®, PET bottle

recycled polyester fiber, was launched.

1996

ECOPET® was adopted for use in

kitchen sink garbage drain bags.

1999

ECOPET® was adopted for use in high tenacity filaments for industrial materials.

2000

Developed the chemical recycling technology

Chemically-recycled ECOPET PLUS® was launched.

2002

Started Eco Circle® (fiber to fiber)

2003

The use of ECOPET PLUS® in banners

and drop curtains started.

ECOPET PLUS® was adopted for use in

company uniforms for female staff.

2004

Received the Minister of Environment Award for Global Warming Prevention Activities.

ECOPET PLUS® was adopted for use in the ties of the uniforms for ministry and agency staff.

ECOPET PLUS® was adopted for use in uniforms.

2005

Eco Circle® received Good Design Award.

ECOPET PLUS® was adopted for use in the uniforms of guards, guards of honor, cleaning staff, and medical staff at EXPO 2005 Aichi, Japan.

2006

T-shirts made using ECOPET PLUS® were provided to the Japan Wheelchair Basketball Championship.

plastic cups for beverages were used at the FIFA Club World Cup Japan 2006.

2007

ECOSTORM®, a high performance waterproof moisture permeable material made using ECOPET PLUS®, was launched.

2008

Functional polo shirts made using ECOPET PLUS® were adopted for use in uniforms for people supporting a professional sports team in Ehime.

A green carpet made using ECOPET PLUS® was used at the 21st Tokyo International Film Festival.

ECOPET® was adopted for use in tire cords for the first time anywhere in the world.

Adoption of ECOPET PLUS® continued in uniform and sportswear industries

2010

Kitakyushu City Government adopted ECOPET PLUS® for winter clothes.

ECOPET PLUS® was adopted for use in the uniforms for cosmetics sales clerks.

Started providing support to the PET bottle recycle activity at a-nation, a music event.

2011

ECOPET PLUS® was adopted for use in

airplane blankets.

ECOPET PLUS® was adopted for use in

medical clothing.

2012

Started plastic cup collection and recycling activities at Hanshin Koshien Stadium.

ECOPET PLUS® was adopted for use in disaster blankets.

2017

Built a global production system for PET bottle recycled fiber ECOPET®.

2018

Variation of ECOPET® differentiating materials was extended (lightweight, UV protection, water absorption, quick drying, etc.)

2020

The ECOPET® brand was expanded to include ECOPET PLUS®.

2021

Developed a mass-production technology of extreme micro polyester fiber using eco-friendly raw materials, which makes all company polyester fibers eco-friendly

- Mechanical recycling

- The process crushes or melts waste plastics and then recycles them into materials for similar uses.

- Chemical recycling

- The process obtains petroleum feedstock by decomposing waste plastics chemically and recycles them as raw materials for products.

Performance Production Performance

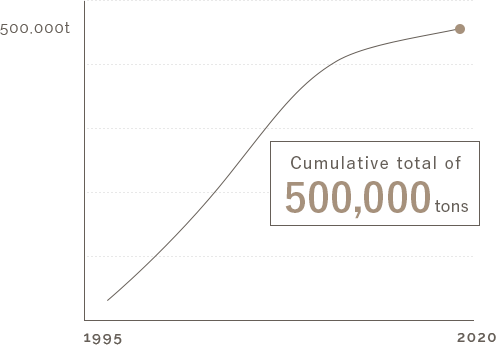

We produced a cumulative total of 500,000 tons of recycled fibers during the period from the inception of ECOPET® in 1995 to March 2020. This corresponds to 25 billion PET bottles or 2.5 billion T-shirts.

Total production of ECOPET®